Return to Table of Contents

Return to Table of Contents

PROCESS/METHODS OF VITAMIN ADDITION

Vitamin fortification can be accomplished by the addition of vitamins at many different points in the processing system, preferably after separation, including the pasteurizing vat, to the HTST constant-level tank, or on a continuous basis into the pipeline after standardization and prior to pasteurization in accordance with the manufacturer's recommendations. Both batch addition and addition with metering pumps can be used. The batch procedure requires accurate measurement of the volume of milk to be fortified, accurate measurement of the vitamin concentrate, and proper mixing. When a vitamin metering pump(s) is used with an HTST or HHST unit the pump(s) must be installed so as to be activated only when the unit is in forward-flow. The addition of vitamins must be accomplished prior to pasteurization in accordance with the manufacturer's recommendations.

The problem of under fortification is often related to the point in the system where fortification takes place. Vitamins A and D are fat-soluble and will gradually become more concentrated in the milk fat portion of the milk. Both oil and water base vitamins are susceptible to this migration problem.

If vitamins are added in the proper amount before separation and standardization, and the product is separated and standardized, then the low fat product will tend to be under fortified and the high fat product over fortified. Water-soluble vitamin concentrates can minimize this problem if vitamins are added before separation. Processors who use this procedure should perform confirmatory assays to ensure proper fortification levels of each product.

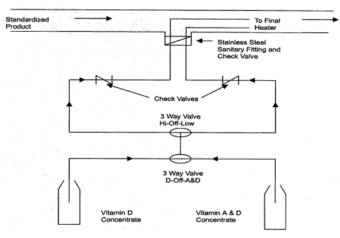

Many HTST systems are now being used with in-line fat standardization, which also makes possible switching, without stopping, from milk and milk products being fortified with Vitamin D to those being fortified with both A and D. These systems require metered injection of the proper vitamins at a point after standardization and before pasteurization. Sanitary positive-displacement pumps are available for this purpose.

There are two (2) types available:

- The first is a piston type metering pump without valves. It is equipped with a micrometer, which allows accurate and reproducible amounts of vitamins to be added based on the rate of product flow through the system.

- The other type is a peristaltic pump that offers precise control. This precise control is possible since the volume can be controlled by the tubing size and the pump speed. This system simplifies cleaning, since only the tube is in contact with the vitamin concentrates.

These pumps have a history of reproducibility and reliability. All metering pumps should be designed to conform with this Ordinance.

The recommended injection point is after separation and prior to homogenization. This allows the homogenization process to distribute the vitamins throughout the milk. A check-valve is recommended to prevent milk from contaminating the vitamin concentrate.

Separate pumps, tubing and check-valves, are recommended when multiple types of vitamin concentrates are injected. (Refer to Figure 46)

YOU MIGHT ALSO LIKE