![Aged variants[edit]](http://petrovskoe.info//img/ricotta_wikipedia_the_free_encyclopedia.jpg)

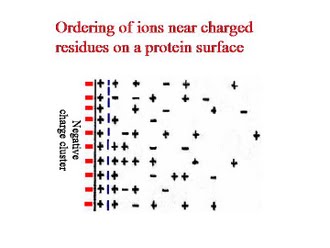

Dispersive or attractive forces exist between proteins through permanent and induced dipoles. For example, basic residues on a protein can have electrostatic interactions with acidic residues on another protein. However, solvation by ions in an electrolytic solution or water will decrease protein-protein attractive forces. Therefore, to precipitate or induce accumulation of proteins, the hydration layer around the protein should be reduced. The purpose of the added reagents in protein precipitation is to reduce the hydration layer.

Precipitate formation[edit]

Protein precipitate formation occurs in a stepwise process. First, a precipitating agent is added and the solution is steadily mixed. Mixing causes the precipitant and protein to collide. Enough mixing time is required for molecules to diffuse across the fluid eddies. Next, proteins undergo a nucleation phase, where submicroscopic sized protein aggregates, or particles, are generated. Growth of these particles is under Brownian diffusion control. Once the particles reach a critical size (0.1 µm to 10 µm for high and low shear fields, respectively), by diffusive addition of individual protein molecules to it, they continue to grow by colliding into each other and sticking or flocculating. This phase occurs at a slower rate. During the final step, called aging in a shear field, the precipitate particles repeatedly collide and stick, then break apart, until a stable mean particle size is reached, which is dependent upon individual proteins. The mechanical strength of the protein particles correlates with the product of the mean shear rate and the aging time, which is known as the Camp number. Aging helps particles withstand the fluid shear forces encountered in pumps and centrifuge feed zones without reducing in size.

Batch reactors[edit]

Batch reactors are the simplest type of precipitation reactor. The precipitating agent is slowly added to the protein solution under mixing. The aggregating protein particles tend to be compact and regular in shape. Since the particles are exposed to a wide range of shear stresses for a long period of time, they tend to be compact, dense and mechanically stable.

Tubular reactors[edit]

In tubular reactors, feed protein solution and the precipitating reagent are contacted in a zone of efficient mixing then fed into long tubes where precipitation takes place. The fluid in volume elements approach plug flow as they move though the tubes of the reactor. Turbulent flow is promoted through wire mesh inserts in the tube. The tubular reactor does not require moving mechanical parts and is inexpensive to build. However, the reactor can become impractically long if the particles aggregate slowly.

Continuous stirred tank reactors (CSTR)[edit]

CSTR reactors run at steady state with a continuous flow of reactants and products in a well-mixed tank. Fresh protein feed contacts slurry that already contains precipitate particles and the precipitation reagents.

Precipitation is widely used in downstream processing of biological products, such as proteins. This unit operation serves to concentrate and fractionate the target product from various contaminants. For example, in the biotechnology industry protein precipitation...

Precipitation is widely used in downstream processing of biological products, such as proteins. This unit operation serves to concentrate and fractionate the target product from various contaminants. For example, in the biotechnology industry protein precipitation...

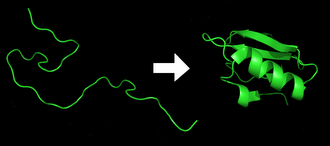

Protein folding is the process by which a protein structure assumes its functional shape or conformation. It is the physical process by which a polypeptide folds into its characteristic and functional three-dimensional structure from random coil. Each protein exists...

Protein folding is the process by which a protein structure assumes its functional shape or conformation. It is the physical process by which a polypeptide folds into its characteristic and functional three-dimensional structure from random coil. Each protein exists...